- Details

- Written by Bob Allan

- Category: Uncategorised

- Hits: 1393

June, 2020

Dear New Elm Lot Owners;

Hoping this note finds everyone well. Unusual times with Covid-19 and travel restrictions affecting us all.

It’s time to pass the hat around again for the road work.

Our historical contribution of $400. per lot per year over the past 12 years has built about 1.9 km of shale-base with gravel-top road together with culverts, ditches, and repairs. A remaining 2.9 km of road has not yet been rebuilt. Our biannual contribution of $800. per lot does more work at one time to decrease some of the costs and 2020 is such a bi-annual contribution and work year.

Our voluntary arrangement has worked well. Some have already asked how to contribute for this year. Previously some folks contributed more than the suggested amount, some contributed in-kind with equipment, labour and materials, and some have contributed annually instead of the double-up. Some folks chose not to contribute the requested amount in past years. We keep all un-spent contributions in the bank ($729.93 today) which neither earns interest nor incurs fees. There are 12 of us owning 14 lots between us. We are all in this together and voluntarily.

Bank account is the same as last time (2018):

Scotiabank: LAHAVE STREET, PO BOX 400 BRIDGEWATER NOVA SCOTIA B4V 2X6

Your account number: 71613 04928 25

Account holder: Robert Allan and Ian Goldsmith (ITF New Elm Estates Lot Owners Road).

We had more traffic and more winter use this year and some sections were plowed. The beavers flooded at the outer pond and we will need to deal with that. The gap around the hill has much improved drainage and is a bit smoother with two new culverts (thanks Ian) but it still needs more work and materials. The most recent (2018) gravel top layer is thin in spots.

Ian Goldsmith (Lot 2) will be doing some pot-hole filling with gravel using his machines and a couple loads of material the week of June 22nd. That will help a lot in the short term and should satisfy the local building trades contractors need for good-enough road to access job sites on our lots.

We are going to wrestle with the beaver for a while clearing culvert to get the water level down in the next couple of weeks. We may need to install a larger culvert and excluder. Ian can do that and would need to coordinate a day of outage for the work.

We worked up some estimates for our current shale-under-gravel method and two gravel-only approaches summarized in the attached future cost estimates. We are thinking about where to use gravel-only road possibly the inner stretch of New Elm Estates from Long Cove Trail to Mint Brook and Long Cove Trail itself. Please tell us your thoughts on that approach.

Urgent needs in priority order for this year are ($15,200): Beaver pond culvert ($1,0000.); gap-section at hill ($11,000 shale/gravel road), gravel cover (1”) on the 2018 section ($2,000.). A contribution budget from every lot is $11,200 which is less than the urgent needs. The work plan must fit the budget. Alternatives include shorten the gap-section, increase contributions and / or half-thickness coarse-gravel construction. Please tell us your suggestions about this also; we’re in it together.

Bob Allan and Ian Goldsmith

- Details

- Written by Bob Allan

- Category: Uncategorised

- Hits: 5267

This stuff previously appeared in the 2016 status update.

We have identified three packages of work that seem most urgent for 2016:

- Cover the previously repaired area with additional gravel at about 170 feet per load (estimating somewhere around 2" deep)

- Complete the hill repair and replace a wooden culvert on the outbound side of the hill [ditching done 2016-08-22]

- Continue the inner rebuilt section out through a wet-spot to the pit.

We have completed (a) as of about Thursday the 18th of August. It looks good. I'll post a video link here shortly so the folks from away can see the new stuff. Materials and cost was: 13 loads $4221. taxes in.

- Video driving tour part 1, the inner secion (High Def)

- Video driving tour, part 2, around the pit hill and up the new section of road (high definition)

We have estimated the cost of (b) at somewhere around $4,800. Caution that Bob made those estimates, not Darell, so we'll soon see if the guess is near. The ditching part was completed 2016-08-22 and it looks like we don't need a culvert.

We have estimated the cost of (c) at about $3,000. Again, caution - non-experts are estimating.

With the funds in the bank (13,987.50), this is all we can afford this year. It will be really close to complete these if our estimates are correct. Watch this space for more updates and links to video and photo as the work progresses.

We took a walk out the road and jotted a few notes as the basis of our current and future plans. All comments are welcome. We are acting within our avaialble funds (above) for the 2016 year and taking votes and offers to "adopt a patch" beyond that.

- Details

- Written by Bob Allan

- Category: Uncategorised

- Hits: 3545

With many hands to make light the work, we had some fun building the beaver excluder on the weekend of 24/25 September, 2016. Thanks to Paul, Natalie, Dave, Marian and Bob.

You can see a short descriptive video here; Talking tour of the beaver excluder

The up-stream side looks like this:

The downstream side looks like this:

A bill of materials:

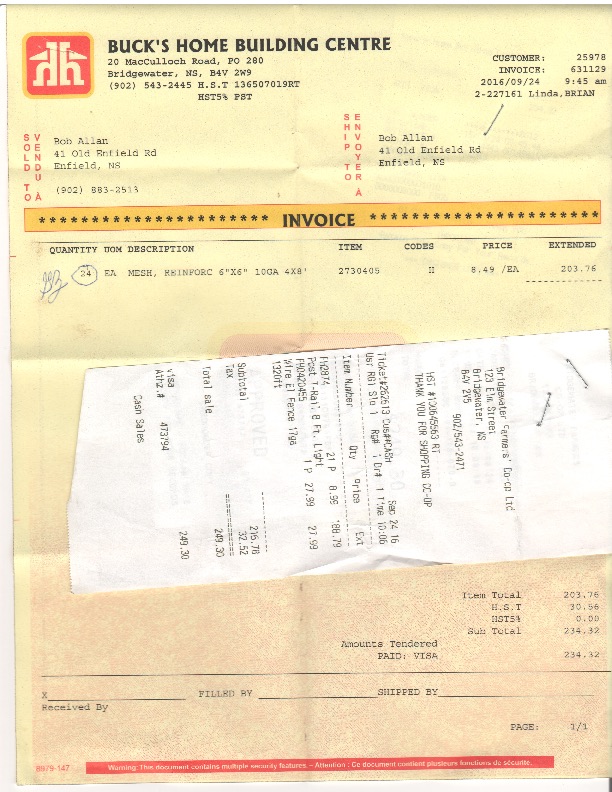

- Reinforcing mesh (like for concrete floors) 6 x 6 mesh, 10 awg, 4 x 8 ft. 22 pieces at $8.49 ea

- T-rail fence posts, 8 feet long, 21 pieces at $8.99

- Wire (electric fence, galvanized, 17 awg) a lot less than the 1320 ft rool at $27,99

- Hog Rings, Malco HR2 Hog Rings, 1000-Pack (we used more than half of those) at $33.

And a receipt"